C&S Propeller Adds Fillet Cut & Cold Roll and Other Specialized Repairs.

The Lockheed C-130 family of aircraft has been in service for over six decades and has earned a reputation around the world as one of the greatest military aircraft ever produced. But its brother the L-100 aircraft, the civilian version of the mighty Hercules, has been flying almost as long and has gained a reputation for reliability, ruggedness, safety, and performance that is no less distinguished than the C-130.

The L-100 aircraft was born on April 20th, 1964, when the first prototype took flight. It entered service in late 1965 when 25 of the aircraft were delivered to Continental Air Services.

In response to slow initial sales, Lockheed responded with the L-100-20 and the L-100-30, both of which were longer, larger, and cheaper to operate than the original version. The L-100 was in production until 1992, with a total of 114 of them delivered to customers around the world. Due to its remarkable history of performance, in 2014 Lockheed formally announced the newest incarnation, the LM-100J.

The L-100, like the C-130, is intended to be capable of carrying large payloads into short, unimproved airfields, although as a civilian model it, of course, has been used for a much wider range of missions than the military model.

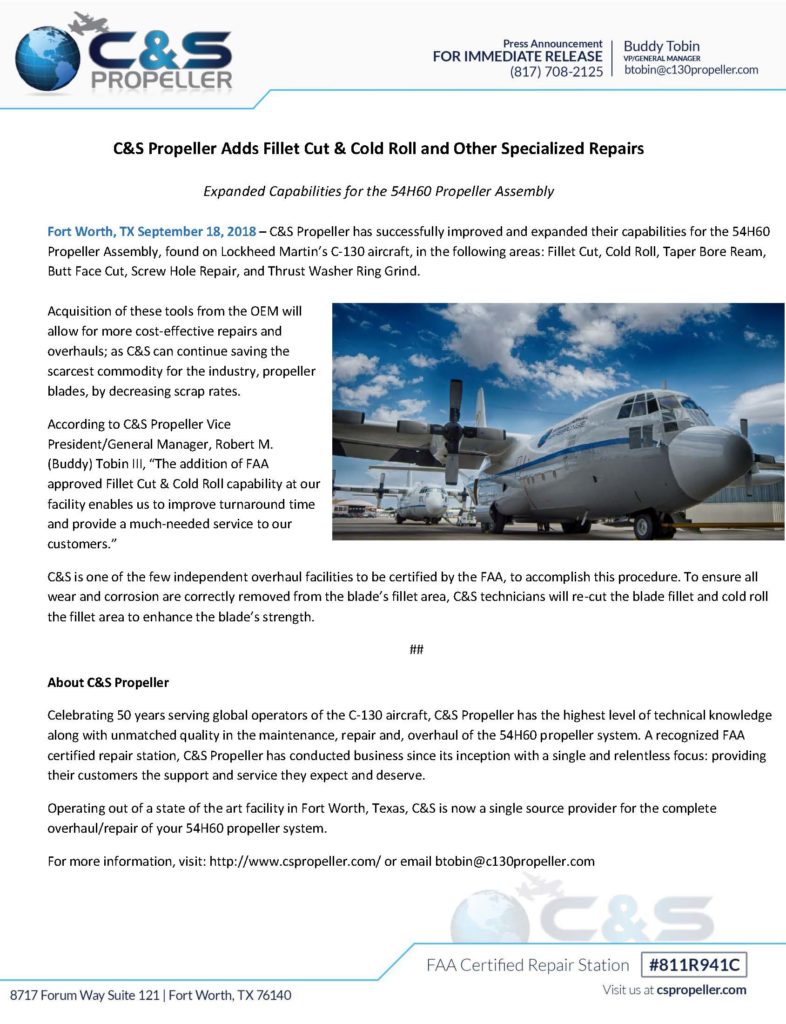

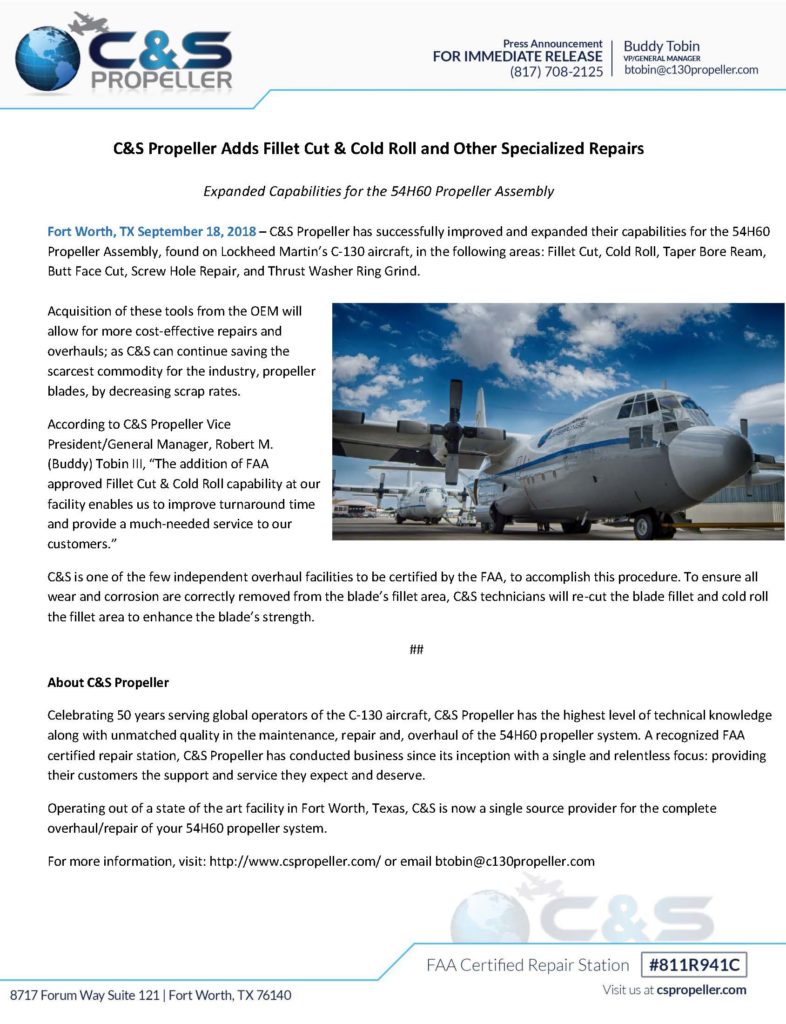

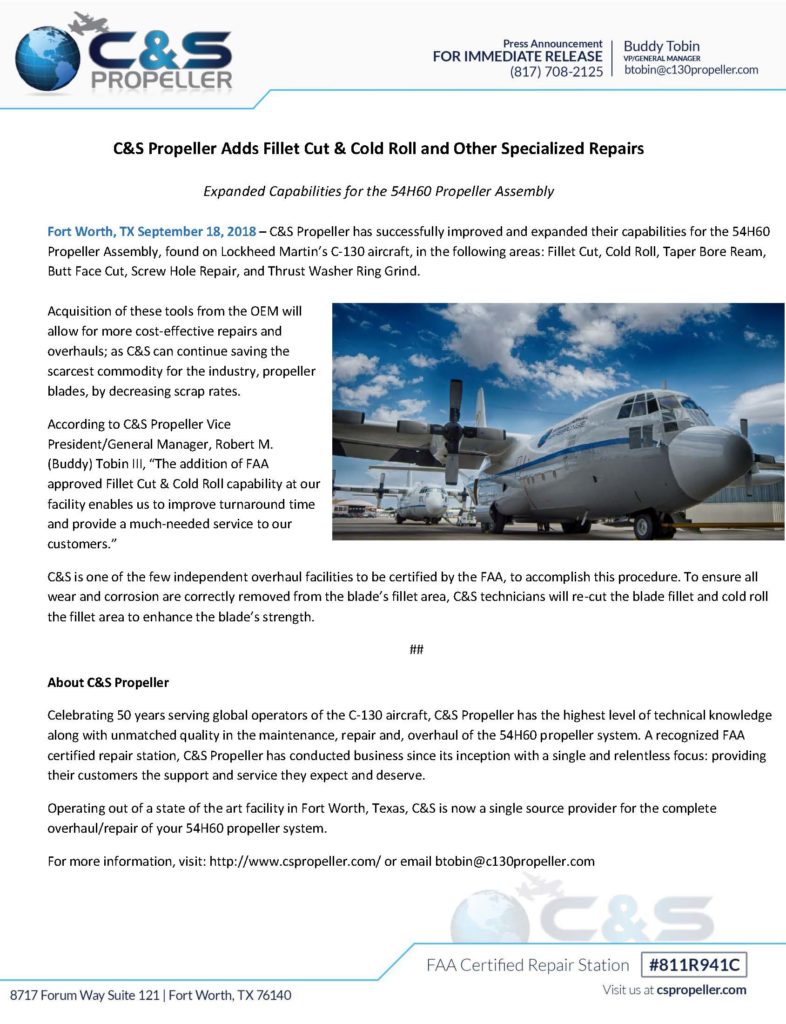

Powered by the superb Hamilton Standard 54H60 four-bladed propeller system on the L-100, its performance is excellent, with a maximum takeoff weight of 155,000 lbs. and a payload of 51,000 lbs., it has a top speed of 355 mph and a cruise of 335, a service ceiling of 23,000 ft., and a rate of -climb of 1,830 fpm. It also boasts a range of 1,800 mi.

The L-100 aircraft is currently in civilian service in 16 countries around the globe, and with the militaries of the Philippines, Saudi Arabia, Algeria, Indonesia, Kuwait, and several smaller nations. Besides carrying cargo and transporting personnel, it has been used for a variety of purposes, including aerial spraying, fire fighting, oil, gas, and mining logistics, humanitarian and air ambulance services, search and rescue, weather research, Arctic exploration and supply, and more. The L-100’s versatility and performance have made it a staple in many industries.

C&S Propeller is one of the primary providers of MRO services for the 54H60 propeller system used on the L-100 aircraft.

In today’s blog post we’ll cover the difference between the 54H60 propeller system and the Dowty R391 propellers. At C&S we provide MRO services for the 54H60, but we get asked all the time about the differences between these two propeller systems that both power the C-130 aircraft.

The C-130 Hercules is one of the most successful aircraft ever built. Known affectionately by the men and women who have served on them as the ‘Herc’, among many other monikers; it has been outstanding at performing its primary mission.

Conceptualized and designed for the U.S. Air Force in response to the evident and changing battlefield realities by the Korean War, Lockheed flew the first prototype, designated then as the YC-130, in 1954; the first operational aircraft, then known as the C-130A, were delivered to the USAF in 1956. The Herc was designed to deliver large payloads onto rough landing strips, with a short takeoff and landing distance. It performed its duties admirably and has since been the first-line workhorse of the military during all of America’s wars and peacetime operations, as well as being heavily utilized for civilian roles. Its versatility is legendary.

During its long operational life, the C-130 has been fitted with four different propeller systems, including Curtis Electric propellers, three-bladed Aeroproducts propellers, the four-bladed Hamilton Standard 54H60 and the six-bladed Dowty R391 propeller, all of them excellent and having their unique strengths, weaknesses and purpose. We’ll take a quick look at two of the most prominent systems, the Hamilton Standard 54H60 and the Dowty R391.

The Dowty R391 propeller system has been used on all the newest version C-130J Super Hercules aircraft. It utilizes a six-bladed, swept-back design with ARA-D/A airfoils, with individual blades constructed of glass and carbon fiber with an inner core of polyurethane foam. A single lever manages the electronic prop control system, which is also integrated with the engine controls, providing simplified operation. This, along with other design features, makes the system very lightweight while delivering good takeoff and climb performance, as well as low levels of noise.

Maintenance on the R391 has also been simplified as much as possible by its modular design and hub construction, a minimum of parts and the lack of complicated and fragile mechanical linkages to the cockpit.

Besides providing power for the C-130J Super Hercules, which is serving in the armed forces of several countries around the world, the Dowty R391 propeller system is also used on the Alenia Aeronautica C-27J Spartan tactical transport and on the ShinMaywa US-1A Kai amphibious aircraft, owned and operated by the Japanese Self-Defense Forces.

Powered by Rolls-Royce AE 2100D3 engines on the C-130J, it has consistently delivered safe and dependable service since the mid 1990’s.

This system uses four propeller blades and is used on many of the legacy models in the C-130 fleet, as well as on the civilian and commercial version, the L-100. It is a constant speed, hydraulically-operated, full-feathering system, providing excellent control and performance in a variety of flight configurations.

Other features include a pitch lock regulator that prevents a sudden decrease in the angle of the blades in the event of a system malfunction, such as the loss of the hydraulic pressure necessary for controlling the propellers, or in the event of an over-speed condition of 103.5%, as well as a low-pitch prop assembly that prevents the propeller blades’ pitch from decreasing below a preselected angle when in the flight range.

The HS 54H60 uses a blade heater for de-icing, and also utilizes a contact de-icing ring to ensure that there is no buildup of ice on the tips of the blades; this can be critical for maximum performance.

The Hamilton Standard 54H60 also has a long history of reliable service.

The 54H60 propeller system have been in service for decades while the Dowty R391 has been in service since 1996. Both will remain a staple of the C-130 fleet for many years to come.

The 54H60 prop system is comparable to the muscles in the human body. It enables flight for the masters of the skies, the C-130 and L-100 aircraft. The model designation and a brief explanation of how the 54H60 functions show how intricate and complex the 54H60 system truly is.

The characters identifying the 54H60 prop system identify specific designs and arrangements of the propeller’s assembly as part of the propeller model designation. Also, each 54H60 prop system model designation is followed by a dash and a number. This ending value refers to the number of minor modifications that have been made to the specific propeller.

The characters of the propeller model designation also define the nature of the propeller system, asserts Lockheed Martin, which breaks down as follows:

So, let’s look at what the 54H60-91 model designation reveals about a particular C-130’s propeller system.

Understanding the designation of the 54H50 propeller system is only the tip of the iceberg, and the functions and capabilities of the system are designed to give the aircraft an immeasurable degree of uses, which accounts for popularity in both military and civilian uses.

The 54H60 propeller assembly is a constant speed, fully feathering, hydro-mechanical propeller. During aircraft operation, the 54H60 prop system has two distinct ranges, beta (ground) and alpha (flight) ranges. These ranges are differentiated by what component is controlling blade angle.

In the beta range, blade angle is controlled by the throttles from 0-34°, but in alpha range, the propeller governor is attempting to maintain a constant speed of 1020 RPM. Conversely, the alpha range is from 34-90°.

The governor’s ability to vary and control blade angle is vital to maintaining the speed and altitude of the C-130 aircraft during flight operations, and the dome of the propeller provides the hydro-mechanical means for adjusting blade angle. The change in blade angle affects the pitch of the propeller. Pitch refers to the distance traveled through the air with one revolution of the propeller. Pitch and blade angle are often used interchangeably. However, blade angle is a measurement as the blades are increased or decreased from the plane of rotation, and pitch is a measurement of distance traveled.

When the governor senses an under-speed (less than 1020 RPM), blade angle must be reduced, allowing the propeller speed (RPM) to increase. The opposite is true when the propeller over-speeds. As an over-speed occurs, the propeller blade angle is too low and must be increased, slowing the propeller to 1020 RPM. The governor porting hydraulic fluid pressure to the dome senses the propeller speed, and then blade angle is hydro-mechanically varied through the dome.

The dome uses a double-acting piston where hydraulic pressure supplied from the governor ports pressure to either the forward side or rear side of the dome piston. When the governor ports hydraulic pressure to the forward side of the dome, blade angle is increased through a rotating cam splined into the blade segment gears. The opposite happens when the governor supplies fluid to the rear side of the dome piston, thus decreasing blade angle.

This variation of blade angle, through the governor and dome, is critical to the safe operation of the 54H60 prop system. For the propeller to remain at a constant speed of 1020 RPM, both of these units must be rigged and adjusted properly. Without the synchronization of the governor and dome working together to vary blade angle, the pitch would constantly be shifting thus slowing or speeding up the aircraft in a straight and level situation. The governor and dome working in tandem allow for this constant RPM to be maintained, without pilot inputs.

The C-130 Hercules has a rich, diverse history, ranging from its origins in military applications to current humanitarian efforts, but part of the driving force behind the might and superiority of the aircraft lies in its propeller system. Four different propeller systems have had the honor of being used to help the C-130 take flight, including Curtis Electric propellers, three-bladed Aeroproducts propellers, the four-bladed Hamilton Standard 54H60 and the six-bladed Dowty R391 propeller. However, all active C-130J aircraft employ the R391. As a result, a thorough understanding of the 54H60 propeller system is essential to keeping older model C-130s and modern L-100 models in operation today.

The components of the 54H60 propeller system have similar names to other propeller systems, explains the Navy BMR. Some of these components include the following:

The 54H60 propeller system is made of up rotating and non-rotating parts. The rotating portions of the propeller system include the barrel assembly, four blade assemblies, and the following components:

Knowing more about the composition of the 54H60 propeller system is the first step toward keeping the legendary “Herc” in service. However, the Herc’s 54H60 propeller system is much more involved in operation than simply identifying its basic parts, and we will dive further into that part of our discussion in Part II.